BRICKS-

COMPOSITION OF BRICKS , MANUFACTURING OF BRICKS

Bricks are obtained by moulding clay in rectangular blocks of uniform size and then by drying and burning these blocks. As bricks are of uniform size, they can be properly arranged, light in weight and hence bricks replace stones.

1.Composition - Manufacture Process.

Composition – Following are the constituents of good brick earth.

Alumina: - It is the chief constituent of every kind of clay. A good brick earth should contain 20 to 30 percent of alumina. This constituent imparts plasticity to earth so that it can be moulded. If alumina is present in excess, raw bricks shrink and warp during drying and burning.

Silica-A good brick earth should contain about 50 to 60 percent of silica. Silica exists in clay either as free or combined form. As free sand, it is mechanically mixed with clay and in combined form; it exists in chemical composition with alumina. Presence of silica prevents crackers shrinking and warping of raw bricks. It thus imparts uniform shape to the bricks. Durability of bricks depends on the proper proportion of silica in brick earth. Excess of silica destroys the cohesion between particles and bricks become brittle.

Lime – A small quantity of lime is desirable in finely powdered state to prevents shrinkage of raw bricks. Excess of lime causes the brick to melt and hence, its shape is last due to the splitting of bricks.

Oxide of iron- A small quantity of oxide of Iron to the extent of 5 to 6 percent is desirable in good brick to imparts red colour to bricks. Excess of oxide of iron makes the bricks dark blue or blackish.

Magnesia- A small quantity of magnesia in brick earth imparts yellow tint to bricks, and decreases shrinkage. But excess of magnesia decreases shrink leads to the decay of bricks.

The ingredients like, lime, iron pyrites, alkalies, pebbles, organic matter should not present in good brick earth.

2. Manufacturing of bricks:

In manufacturing of brick, the following operations are involved

1. Preparation of clay

2. Moulding

3. Drying

4. Burning

(i) Preparation of clay :- The preparation of clay involves following operations

a) Unsoiling :- Top layer of 20cm depth is removed as it contain impurities.

b) Digging: - Clay dug out from ground is spread on level ground about 60cm to 120cm heaps.

c) Cleaning:-Stones, pebbles, vegetable matter etc removed and converted into powder form.

d) Weathering:- Clay is exposed to atmosphere from few weeks to full season.

e) Blending:- Clay is made loose and any ingredient to be added to it is spread out at top and turning it up and down in vertical direction.

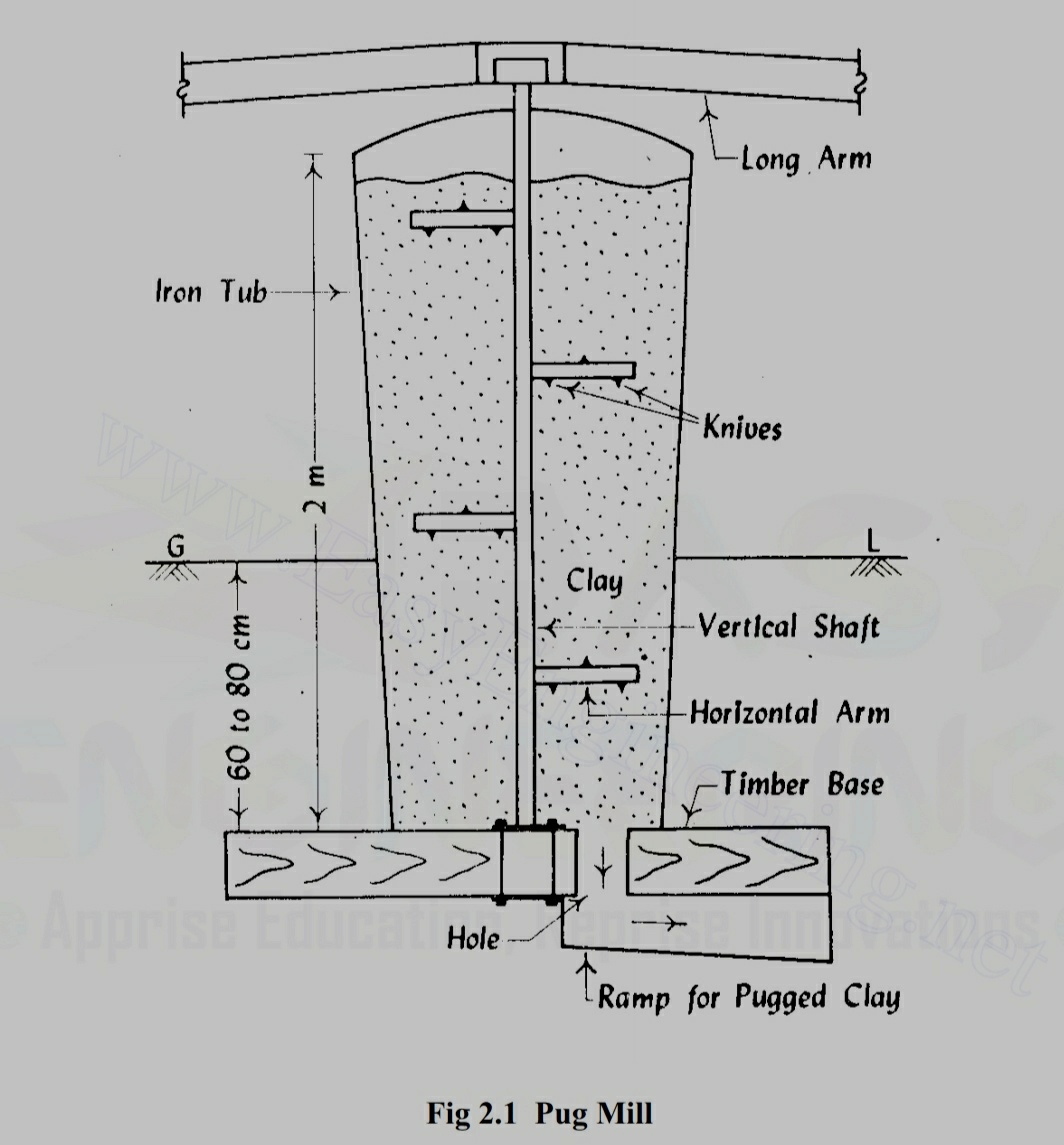

f) Tempering:- Clay is brought to a proper degree of hardness, then water is added to clay and whole mass is kneaded or pressed under the feet of men or cattle for large scale, tempering is usually done in pug mill as shown in the fig

Process:- Clay with water is placed in pug mill from the top. When the vertical staff is rotated by using electric pair, steam or diesel or turned by pair of bullocks. Clay is thoroughly mixed up by the actions of horizontal arms and knives when clay has been sufficiently pugged, hole at the bottom of tub, is opened cut and the pugged earth is taken out from ramp for the next operation of moulding.

ii) Moulding: Clay, which is prepared form pug mill, is sent for the next operation of moulding. Following are the two ways of moulding.

Hand Moulding: Moulds are rectangular boxes of wood or steel, which are open at top and bottom. Steel moulds are more durable and used for manufacturing bricks on large scale as shown in fig . Bricks prepared by hand moulding are of two types.

a) Ground moulded bricks

b) Table moulded bricks

(a) Ground moulded bricks: ground is first made level and fine sand is sprinkled over it. Mould is dipped in water and placed over the ground to fill the clay. Extra clay is removed by wooden or metal strike after the mould is filled forced mould is then lifted up and raw brick is left on the ground. Mould is then dipped in water every time lower faces of ground moulded bricks are rough and it is not possible to place frog on such bricks. Ground moulded bricks of better quality and with frogs on their surface are made by using a pair of pallet boards and a wooden block .

(b) Table-moulded bricks: Process of moulding these bricks is just similar to ground bricks on a table of size about 2m x 1m.

Machine moulding: This method proves to be economical when bricks in huge quantity are to be manufactured at the same spot. It is also helpful for moulding hard and string clay. These machines are broadly classified in two categories

(a) Plastic clay machines

(b) Dry clay machines

a) Plastic clay machines: This machine containing rectangular opening of size equal to length and width of a brick. Pugged clay is placed in the machine and as it comes out through the opening, it is cut into strips by wires fixed in frames, so there bricks are called wire cut bricks.

b) Dry clay machines: In these machines, strong clay is first converted into powder form and then water is added to form a stiff plastic paste. Such paste is placed in mould and pressed by machine to form hard and well shaped bricks. These bricks are behavior than ordinary hand moulded bricks. They carry distinct frogs and exhibit uniform texture.

(3) Drying: The damp bricks, if burnt, are likely to be cracked and distorted. Hence moulded bricks are dried before thay are taken for the next operation of burning. Bricks are laid along and across the stock in alternate layers. The drying of brick is by the following means

(i) Artificial drying – drying by tunnels usually 1200C about 1 to 3 days

(ii) Circulation of air- Stacks are arranged in such a way that sufficient air space is left between them free circulation of air.

(iii)Drying yard- special yards should be prepared slightly higher level prevent the accumulation of rain water

(iv)Period for frying – usually about 3 to 10 days to bricks to become dry

(v) Screens – screens are necessary, may be provided to avoid direct exposure to wind or sun.

(4) Burning: This is very important operation in the manufacturing of bricks to impart hardness, strength and makes them dense and durable. Burning of bricks is done either in clamps or in kilns. Clamps are temporary structures and they are adopted to manufacture bricks on small scale. Kilns are permanent structures and they are adopted to manufacture bricks on a large scale. A typical clamp is as shown in fig.

(1) A trapezoidal shape in plan with shorter is slightly in excavation and wider end raised at an angle of 150 from ground level .

(2) A brick wall with mud is constructed on the short end and a layer of 70cm to 80cm thick fuel (grass, cow dung, ground nuts, wood or coal) laid on the floor.

(3) A layer consists of 4 or 5 courses of raw bricks laid on edges with small spaces between them for circulation of air .

(4) A second layer of fuel is then placed, and over it another layer of raw bricks is put up. The total height of clamp in alternate layers of brick is about 3 to 4 m.

(5) When clamp is completely constructed, it is plastered with mud on sides and top and filled with earth to prevent the escape of heat .

(6) The period of burning is about one to two months and allow the same time for coding .

(7) Burnt bricks are taken out from the clamp.

Tags: bricks , composition of bricks , components of bricks , manufacturing of bricks, what are the composition of bricks, manufacturing process of brick ,Steps of manufacturing of bricks

0 Comments